Serpentine Drive Belts

What causes a serpentine belt to fail?

Most common causes for belt failure:

- Age. It is simply worn by use, heat, friction, ozone exposure, and low/high temperatures (cracked, missing ribs, etc)

- Misalignment of the pulleys driven by the belt

- A hardened pulley from any of the accessories driven by the belt (alternator, A/C compressor, etc.)

- A failing belt tensioner (weak spring or worn bearing)

- Contamination of the belt (oil or coolant leak)

Like any other part of your car, the serpentine drive belt wears out over time due to heat, friction, and age. Serpentine belts may also fail due to issues such as misaligned pulleys or accessories that fail or lock up. For example, if the alternator gets damaged in a way that offers more resistance to its rotational movement, since the alternator is driven (moved) by the serpentine belt, it means that an extra load will be applied to that belt. If, on the other hand, the alternator gets locked entirely, the serpentine belt will slip over its pulley, possibly creating a squealing noise and overheating.

In other cases, the problem with a pulley from any accessory is subtle and creates a failure over time. That is why it is essential to periodically check the belt for cracks or a glazed appearance, even if everything appears to be working well.

Contrary to the trapezoidal or “V” belts, the serpentine belt is wide and has grooves to align with the grooved pulleys of the accessories, and as the grooves of the belt wear over time, the belt may slip and heat, sustaining even more damage.

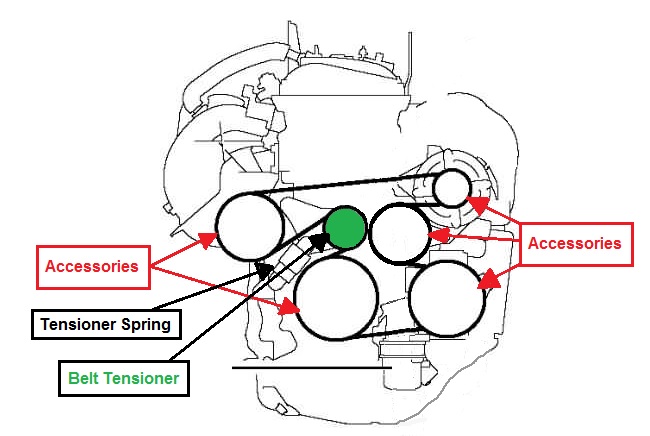

Belt Tensioner

The belt must have a certain tension to work properly, not loose, not overtensioned, just as tight as recommended by the manufacturer. The way to keep the tension even when the belt wears out over time is either by an automatic belt tensioner (spring-loaded), or by adjusting the angle of some accessory, like, in most cases, the alternator.

If a tensioner is used, it is important to always check the condition of the tensioner when checking the belt, and when the time of replacing the belt comes, replace the tensioner too.

How to know if the belt is bad, or getting bad?

If it squeaks or you notice unusual noises, or has visible cracks, fraying, or glazing, it is an indication that your belt is in a bad condition and it is time for a replacement. Another indication can be if belt-driven components, like the alternator, malfunction intermittently. These are telltale symptoms of a bad serpentine belt and should not be ignored, as continued use can lead to complete belt failure. About the cracks, mechanics often measure it in “cracks per inch”, where too many to be accepted would be more than 4 to 5 cracks per inch.

If it makes unusual noises, you should know that it is not always a failure of the belt itself. Remember that the serpentine belt drives (moves) many pulleys from different components, like the water pump, the alternator, the AC compressor, and so on. If one of those components or even their pulleys sustains some damage, the serpentine belt will “feel” it.

So, if your serpentine belt is near its replacement time, then yes, go ahead and replace it. If it is not, then you should first check the pulleys and components that the belt drives, to make sure that the problem is not caused by any of them, before replacing the belt.

Example of a damaged belt:

Comparison of a damaged vs a good belt:

Can I drive my car if the serpentine is squawking?

Technically, yes, you can drive with a squeaky belt for short distances, but it is not recommended.

If the belt fails completely, you could lose essential functions like power steering, that may cause an accident, or the air conditioning, or lose electrical charging, that will cause the car to keep running while the remaining charge in the battery lasts, and the engine will die out as soon as that charge is depleted, having no power for ignition, and leaving you stranded.

All the previous consequences caused by a broken belt are bad, especially the one with the power steering due to the risk of personal injury in a possible accident, but to add to the list, there is a risk of damaging your engine by overheating due to the water pump not circulating coolant, as it is also driven by the serpentine belt in many engine designs.

Are sprays sold for these belts any good?

Engine belt conditioner sprays are generally not recommended by mechanics, and they can often cause more harm than good. They are only temporary solutions if anything, and are only meant to fix the belt squealing, not the mechanical problem causing it.

The spray, at best, is largely considered a temporary solution if something is achieved, and at worst, it is the cause of a premature failure.

Why is this? Especially with all the hype about those sprays?

Because a spray helps by quieting the noise without addressing the root cause of the problem. A spray that is intended for better grip or for conditioning the rubber has a sticky substance and ends up attracting more dirt and debris. This has an abrasive property, like sandpaper, that may accelerate the wear of the belt and/or the pulleys.

So belt sprays are temporary or for emergency cases only, while you can bring your car to a mechanic shop to diagnose the problem or to replace the belt.

If you must use a spray as a temporary fix, the most recommended and frequently mentioned is the CRC Belt Conditioner. Even CRC states that it is for the temporary silencing of belt squeals on properly tensioned and aligned belts. They do not claim to significantly extend the belt’s life. What makes it recommendable is that it is a dry-type dressing designed to be less sticky and attract less dirt than other products. Instead of adding something to the belt’s surface, the main idea of the product is to remove any material from the surface of the belt, hopefully creating a better grip.

How much does it cost to put a serpentine belt on?

The cost to replace a serpentine belt in the US can vary widely based on several factors, but here’s a detailed breakdown. The typical total cost range is $100 to $280 for the most common passenger vehicles, including small trucks. This is $25 to $80 for the belt alone, plus $75 to $200 for the labor.

However, if the belt failed due to a seized pulley (like the idler or tensioner), the cost will increase to replace those additional parts. Also, on some vehicles, like transverse V6 engines, some BMWs, Audis, or older Subarus, the job can require removing engine covers, components, or even motor mounts, taking 1-1/2 to 2-1/2+ hours, making that previous calculation higher.

Note: Some shops may charge a small fee to inspect the belt and diagnose noise or wear, which is often waived if you do the repair with them.

Can I replace the serpentine belt myself?

Replacing a serpentine belt yourself is a moderately easy Do-It-Yourself (DIY) job for someone with basic mechanical aptitude, common hand tools, and a little patience. The difficulty of the job depends on the design of the vehicle, the engine bay access, and whether the car uses an automatic belt tensioner.

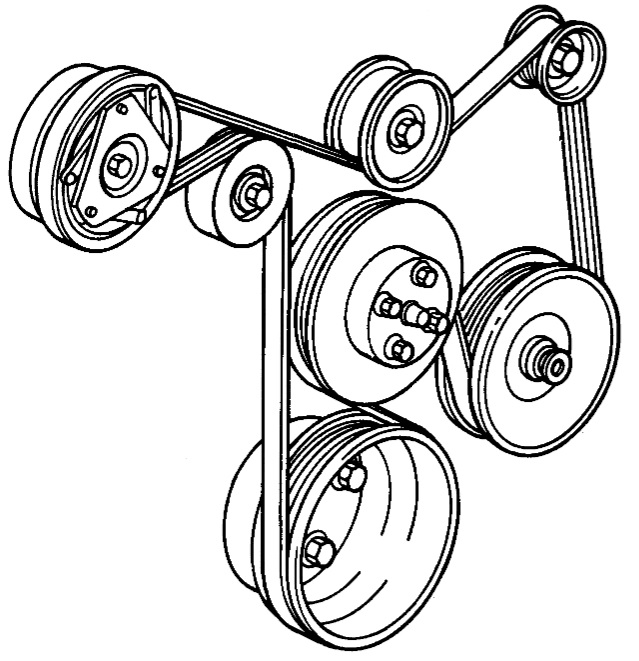

The job may require removing some plastic or metallic covers, and you should memorize, take a picture, or even look over the internet for a diagram of the configuration of the belt. That is, the path of the belt over the different pulleys that it drives.

If it has a tensioner, and it is an automatic one, you will have to remove it or loosen it before installing the belt, and then put it back when the belt is installed. If there is no tensioner, there will be an accessory, usually the alternator, with a bolt that can be loosened to allow rotation in order to loosen the belt, and then tension it back to the manufacturer’s recommendation.

This, in all, is quite an easy job, but if you feel that it is too much for you, then you can bring it to a local mechanic. This is a job that a mechanic can do in less than an hour, and you should be able to wait for it, depending on the mechanic’s work load of the day.

Can you put a serpentine belt on wrong?

Yes. The serpentine belt has grooves. So putting it upside down is out of the question. But still, it can be put wrong in the sense of the path around the pulleys, because in many cases, the specific length of the belt will fit in more than one way around the pulleys. That is why it is very important to take a picture of your old belt first before uninstalling it, or in cases where the belt broke and fell off, looking over the internet for the configuration diagram of your specific engine, or by referencing the exact year, make, and model.

How long does a serpentine belt usually last?

Given that all accessories and pulleys driven by the serpentine belt are ok, these belts typically last from 50,000 to 100,000 miles. Heat, friction, exposure to ozone, and failing components driven by the belt are the major causes for shortening their lifespan.

If you suspect that your belt might be failing, do a visual inspection of the belt. Always look for cracks, glazing, or even if it seems like something is detaching from it, like threads from the reinforcing cords inside the belt.